What are you looking for?

5 Axis CNC Machining

We offers a wide range of CNC milling processes to produce precise and complex parts with high-dimensional tolerances:

1. CNC three-axis

2. CNC four-axis

3. CNC five-axis

4. Milling machine

5 Axis CNC Machining

We offers a wide range of CNC milling processes to produce precise and complex parts with high-dimensional tolerances:

1. CNC three-axis

2. CNC four-axis

3. CNC five-axis

4. Milling machine

SLA (Stereolithography) 3D Printing

3D printing, a type of rapid prototyping technology, is a technology that uses powdered metal or plastic and other bondable materials to construct objects based on digital model files through layer-by-layer printing. The material used for SLS is nylon FS3300PA) solid powder, nylon + glass fiber (FS3400GF) solid powder processing accuracy: ±0.2mm /100mm, the largest overall molding size: 350*350*420mm.

SLA (Stereolithography) 3D Printing

3D printing, a type of rapid prototyping technology, is a technology that uses powdered metal or plastic and other bondable materials to construct objects based on digital model files through layer-by-layer printing. The material used for SLS is nylon FS3300PA) solid powder, nylon + glass fiber (FS3400GF) solid powder processing accuracy: ±0.2mm /100mm, the largest overall molding size: 350*350*420mm.

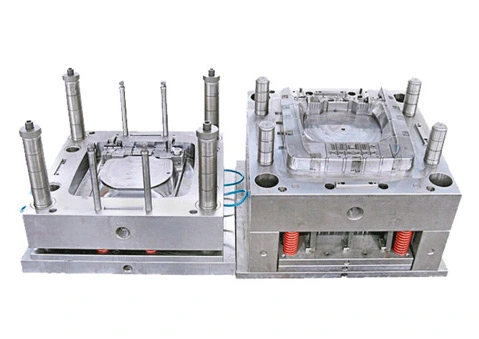

Plastic Injection Molding

Injection mold processing technology also has the characteristics of high efficiency, accuracy, strong applicability, short production cycle, etc. With the continuous development and innovation of science and technology, the efficiency of injection mold processing and the quality of finished products have been further improved.

Plastic Injection Molding

Injection mold processing technology also has the characteristics of high efficiency, accuracy, strong applicability, short production cycle, etc. With the continuous development and innovation of science and technology, the efficiency of injection mold processing and the quality of finished products have been further improved.

Turn-milling Machining

At Essai, our CNC lathe is an high efficient and profitable solution to complex cylindrical parts like slot, knurling with high dimension tolerance. Advanced and automatic machines enable us to manufacture geometrical parts with low tolerance faster and easier.

Turn-milling Machining

At Essai, our CNC lathe is an high efficient and profitable solution to complex cylindrical parts like slot, knurling with high dimension tolerance. Advanced and automatic machines enable us to manufacture geometrical parts with low tolerance faster and easier.

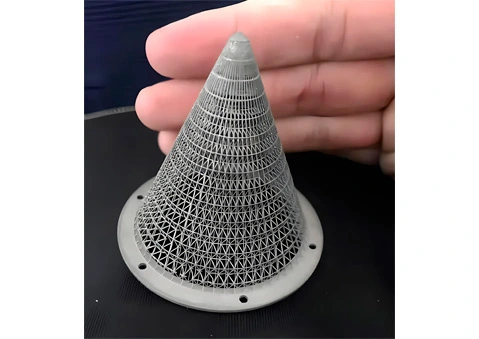

SLS (Selective Laser Sintering) 3D Printing

The automotive industry has greatly benefited from the adoption of SLS printing, enabling rapid production of prototypes, end-use parts and molds. The technology's ability to manufacture complex, lightweight components improves vehicle performance, efficiency and customization, making it an indispensable tool for automakers.

SLS (Selective Laser Sintering) 3D Printing

The automotive industry has greatly benefited from the adoption of SLS printing, enabling rapid production of prototypes, end-use parts and molds. The technology's ability to manufacture complex, lightweight components improves vehicle performance, efficiency and customization, making it an indispensable tool for automakers.

Metal Injection Molding

Metal injection molding, abbreviated as MIM (Metal Injection Molding) This is a method of mixing metal powders and adhesives for injection molding. MIM is widely used in consumer electronics, auto parts, medical devices, power tools, industrial equipment and daily necessities.

MIM can process metal data including low alloy steel, stainless steel, tool steel, nickel base alloy, tungsten alloy, hard alloy, titanium alloy, magnetic data, Kovar alloy, precision ceramics and so on.

Metal Injection Molding

Metal injection molding, abbreviated as MIM (Metal Injection Molding) This is a method of mixing metal powders and adhesives for injection molding. MIM is widely used in consumer electronics, auto parts, medical devices, power tools, industrial equipment and daily necessities.

MIM can process metal data including low alloy steel, stainless steel, tool steel, nickel base alloy, tungsten alloy, hard alloy, titanium alloy, magnetic data, Kovar alloy, precision ceramics and so on.

SLM 3D Printing

SLM metal 3D printing technology is a typical additive manufacturing technology. Its principle is to selectively heat the metal powder through a laser beam, melt it into a liquid state, form it layer by layer on a substrate stacked layer by layer, and finally obtain the required 3D-printed metal parts.

SLM 3D Printing

SLM metal 3D printing technology is a typical additive manufacturing technology. Its principle is to selectively heat the metal powder through a laser beam, melt it into a liquid state, form it layer by layer on a substrate stacked layer by layer, and finally obtain the required 3D-printed metal parts.

Sheet Metal Prototyping

Sheet metal processing is a comprehensive cold processing process for sheet metal, mainly including cutting, punching/cutting/compounding, folding, riveting, splicing, forming and other processes. Thi...

Sheet Metal Prototyping

Sheet metal processing is a comprehensive cold processing process for sheet metal, mainly including cutting, punching/cutting/compounding, folding, riveting, splicing, forming and other processes. Thi...

Over Molding & Insertmolding

Over Molding is a kind of double injection molding process, which is usually formed by two kinds of plastic materials in two times, and the product is removed after the first injection molding, and then put into another set of molds or another cavity for the second injection molding.

Over Molding & Insertmolding

Over Molding is a kind of double injection molding process, which is usually formed by two kinds of plastic materials in two times, and the product is removed after the first injection molding, and then put into another set of molds or another cavity for the second injection molding.

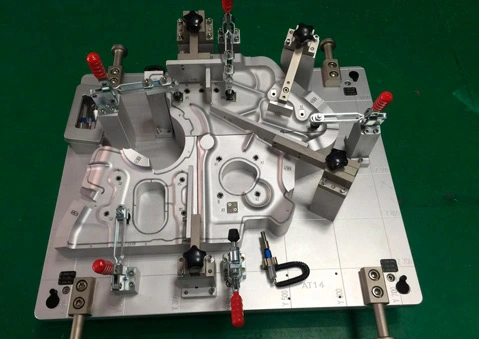

Automotive Inspect/Welding Jigs

The function of automobile welding fixture is to realize the correct assembly of body parts, ensure the correct collocation of parts and complete welding. In engineering, the design of automotive welding fixture is usually evaluated from the aspects of assembly accuracy, shortening manufacturing cycle and adjustability. Positioning is the most basic element of the welding fixture, but also the main consideration of the design process, positioning design standardization to a large extent to improve the performance of the welding fixture, shorten the cycle, improve efficiency.

Automotive Inspect/Welding Jigs

The function of automobile welding fixture is to realize the correct assembly of body parts, ensure the correct collocation of parts and complete welding. In engineering, the design of automotive welding fixture is usually evaluated from the aspects of assembly accuracy, shortening manufacturing cycle and adjustability. Positioning is the most basic element of the welding fixture, but also the main consideration of the design process, positioning design standardization to a large extent to improve the performance of the welding fixture, shorten the cycle, improve efficiency.

Fixtures and Fittings

Essai has a long history and rich experience. It can cooperate with customers of OEM / JDM / ODM projects with high quality and cost-effectiveness under the rapid development time, customization and differentiated specifications. We can quickly customize various products according to customer needs. For design and processing drawings, the Essai engineering service team is composed of experts in their respective fields. We focus on our talents and efforts to create effective solutions for our customers.

Fixtures and Fittings

Essai has a long history and rich experience. It can cooperate with customers of OEM / JDM / ODM projects with high quality and cost-effectiveness under the rapid development time, customization and differentiated specifications. We can quickly customize various products according to customer needs. For design and processing drawings, the Essai engineering service team is composed of experts in their respective fields. We focus on our talents and efforts to create effective solutions for our customers.

Steel Progressive Die

Our precision-engineered progressive dies to ensure efficient and simultaneous cutting, bending, and shaping of metal sheets, maximizing productivity. In the feeding direction of the strip, there are more than two stations, and two or more stamping processes are completed at the same time.

Steel Progressive Die

Our precision-engineered progressive dies to ensure efficient and simultaneous cutting, bending, and shaping of metal sheets, maximizing productivity. In the feeding direction of the strip, there are more than two stations, and two or more stamping processes are completed at the same time.

Automotive Stamping Dies

The multi-station progressive die will be one of the key developments of the die products in our country, the shape of complex stamping parts, especially some according to the traditional process needs more and more pairs of punching die sequence punching small and medium-sized complex stamping parts, more and more the use of progressive die forming.

Automotive Stamping Dies

The multi-station progressive die will be one of the key developments of the die products in our country, the shape of complex stamping parts, especially some according to the traditional process needs more and more pairs of punching die sequence punching small and medium-sized complex stamping parts, more and more the use of progressive die forming.

Precision Shaft

Essai focus on precision shaft customization processing, high precision grinding machine processing with tolerance 0.003mm for low volume and mass production.

Precision Shaft

Essai focus on precision shaft customization processing, high precision grinding machine processing with tolerance 0.003mm for low volume and mass production.

Deep Drawing Die

Designed for producing deep-drawn metal components, our deep draw dies guarantee excellent dimensional accuracy and uniformity across high-volume production runs.

Deep Drawing Die

Designed for producing deep-drawn metal components, our deep draw dies guarantee excellent dimensional accuracy and uniformity across high-volume production runs.